-

High Temperature Resistance

Specially engineered for continuous operation in extremely high temperatures, typically up to 1300°C or higher. -

Superior Material Durability

Constructed with high-grade materials such as Inconel, Hastelloy, or noble metal alloys to withstand aggressive furnace environments. -

Anti-coking and Corrosion Resistant Design

Designed to resist carbon build-up and corrosion caused by hydrocarbons and high-temperature gases in pyrolysis conditions. -

Accurate and Stable Measurement

Ensures reliable and precise temperature control, critical for optimizing cracking efficiency and product yield. -

Customizable for Harsh Environments

Available in various sheath types, lengths, and protection tube options to meet specific furnace configurations. -

Extended Service Life

Designed for long operational periods, reducing the frequency of replacements and minimizing downtime. -

Quick Response Time

Maintains fast thermal response even in shielded or armored configurations. -

Field-proven in Petrochemical Plants

Widely used and validated in major ethylene, hydrogen, and refinery cracking units worldwide.

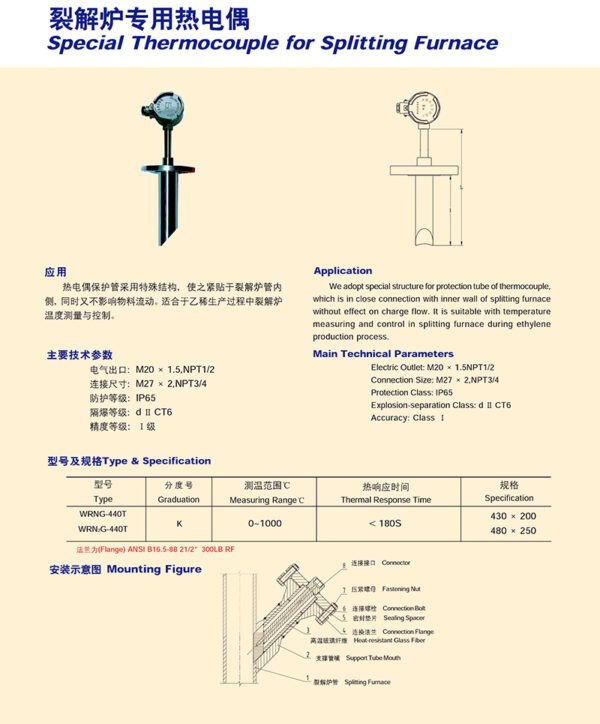

Special Thermocouple for Cracking Furnace

$1,000.00

Reviews

There are no reviews yet.