1. Application Scenarios of Spray-proof Armored Thermocouples

Spray-proof armored thermocouples are designed for use in high-pressure chemical pipelines to prevent medium ejection accidents. They are widely used in industrial environments where high-pressure, high-temperature, or corrosive media are present. They are specifically designed to ensure operator safety and reliable temperature measurement in the following scenarios:

-

Chemical and Petrochemical Plants

For temperature measurement in pressurized pipelines containing hazardous fluids such as ammonia, hydrogen, or hydrocarbon mixtures, where accidental spray or leakage could pose safety risks. -

Synthetic Ammonia Production Units

Installed in high-pressure reactors or pipelines to monitor process temperatures, while preventing medium ejection due to sensor failure or seal rupture. -

Refineries and Oil & Gas Pipelines

Used in flammable or explosive environments where both armored protection and spray-proof sealing are required to ensure system integrity. -

High-pressure Steam Systems

For monitoring temperatures in boilers or steam lines where sudden discharge of steam must be contained by the thermocouple’s protective structure. -

Other Hazardous Process Areas

Any environment where process media under pressure could spray out upon thermocouple failure, including power plants, pharmaceutical reactors, and chemical mixing vessels.

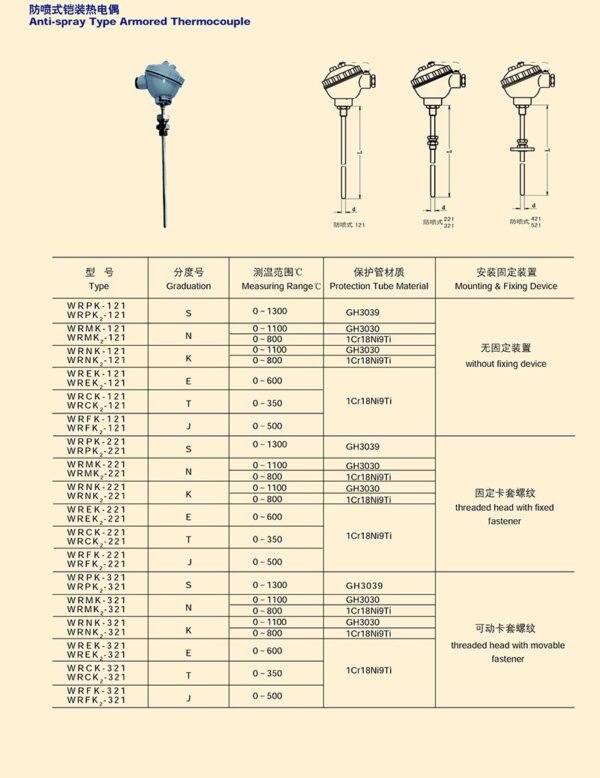

2. Main Technical Parameters

-

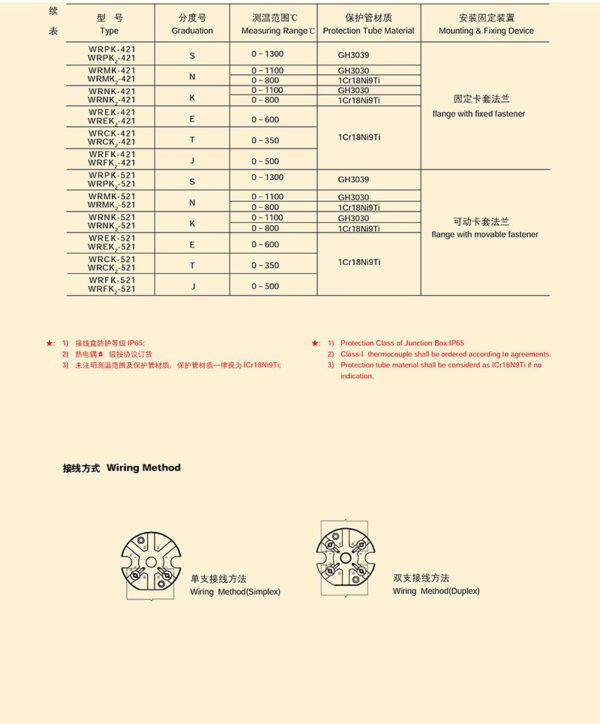

Accuracy Class: Class I

-

Protection Rating: IP65

Reviews

There are no reviews yet.