Working Principle

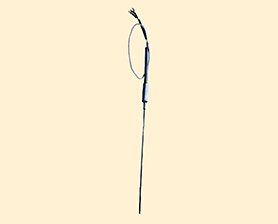

A micro-sized armored thermocouple operates based on the Seebeck effect, where two dissimilar metals are joined together at one end (the measuring junction) to create a small voltage proportional to the temperature difference between the measurement and reference points.

The armored design protects the thermocouple element from mechanical damage, chemicals, and extreme environmental conditions. This design ensures that the sensitive thermocouple junction remains intact and functional while providing accurate temperature measurements, even in the harshest environments.

- Thermoelectric Voltage Generation: The change in temperature causes the two dissimilar metal wires to generate a thermoelectric voltage, which can be translated into a temperature reading.

- Armored Protection: The protective sheath (or armor) ensures that the thermocouple is resistant to physical stress, corrosion, and high temperatures.

Applications

Micro-sized armored thermocouples are used in a wide variety of precision applications where small size, durability, and accuracy are essential. Some common applications include:

- Semiconductor industry: Monitoring temperatures in cleanrooms, furnace tubes, or microchip manufacturing processes.

- Aerospace: Used for high-precision temperature measurements in aircraft engines, turbines, and propulsion systems.

- Automotive testing: Ideal for testing high-performance engines and components where space is constrained.

- Medical devices: Monitoring temperatures in compact or embedded devices like wearable health sensors or implantable devices.

- Pharmaceutical manufacturing: Ensuring precise temperature control in critical environments such as freeze-drying or vaccination storage.

- Research and development: Perfect for laboratory testing where small, highly accurate sensors are required.

- Oil and gas: Used for temperature monitoring in offshore rigs and subsea equipment, where environmental protection and precision are critical.

Materials and Construction

- Thermocouple Elements:

- Typically made from alloys like Nickel-Chromium (Type K), Iron-Constantan (Type J), Platinum-Rhodium (Type S, R, or B), and Nickel-Chromium-Silicon (Type N).

- Micro-sized thermocouples are designed with fine wires (often ranging from 0.2 mm to 1.5 mm in diameter) for highly sensitive and localized temperature measurements.

- Armored Sheath:

- Stainless Steel 304/316L or Inconel alloys are common sheath materials due to their excellent corrosion resistance and high-temperature performance.

- For applications in extremely aggressive environments, materials like tantalum or Hastelloy may be used to ensure durability against acidic or corrosive agents.

- Insulation:

- Mineral Insulated (MI) Cable: Offers superior heat resistance and protection against mechanical stress.

- Other insulation types include ceramic, Teflon, or fiberglass depending on the temperature range and environment.

- End Fittings & Terminations:

- The micro-sized armored thermocouple typically includes spring-loaded fittings, flanged connectors, or custom terminals to suit different installation setups.

Technical Features & Benefits

- Compact and Space-Saving

With its miniature size, it is ideal for applications where space is limited or where precision is required in small, confined spaces. - High-Temperature Capability

Can measure temperatures from -200°C to +2000°C, depending on the type of thermocouple and the materials used for insulation and armor. - Fast Response Time

The small size of the thermocouple allows for quick temperature changes detection, offering superior response time in dynamic processes. - Durable and Corrosion-Resistant

The armored design offers excellent protection against vibration, abrasion, corrosion, and high-pressure conditions, ensuring long-term reliability in industrial environments. - High Precision

Provides accurate and stable temperature measurements, even in environments exposed to extreme physical and chemical stress. - Versatile and Customizable

Available in a range of diameters, lengths, and connection types to meet specific industrial requirements. Custom designs are available for special applications like explosive environments or sterile medical devices. - Easy Integration

Compatible with various industrial control systems, PLC setups, temperature transmitters, and data loggers, ensuring seamless integration into automated systems.

Advantages Over Standard Thermocouples

- Miniaturization without Compromise on Performance

Provides precision and durability while maintaining a compact size, perfect for small, high-performance equipment. - Enhanced Durability in Harsh Environments

Ideal for applications where standard thermocouples would fail due to harsh mechanical, chemical, or temperature stresses. - Cost-Effective Solution

Offers an affordable way to integrate high-performance sensors into precision applications without the need for expensive alternatives.